Traditionally, assessing wear on rope drum coupling connections requires visual or tactile inspections, often conducted in hard-to-reach areas. Accessing the hoist unit can be lengthy and hazardous, necessitating the shutdown of both equipment and crane. This extensive monitoring process negatively impacts productivity and consumes valuable time from skilled personnel.

Due to the nature of rope drum coupling applications and their extended service life, detecting wear becomes particularly challenging towards the end of the component’s life cycle. Accurately reading wear measurements with a precision of 1mm is already difficult, and with wear rates as low as tenths of a millimetre per year, ensuring full utilisation of the component’s lifespan is nearly impossible.

Advanced monitoring with up to eight sensors

With LifeMonitor technology, these challenges become a thing of the past. Continuous wear monitoring enables precise measurement of the remaining wear reserve. Based on the linear wear behaviour of barrel couplings – unlike gear couplings, which exhibit different patterns – LifeMonitor technology can accurately predict the remaining service life of the rope drum coupling. This makes LifeMonitor an essential component for redictive and condition-based maintenance. By accurately determining wear and wear rate, operators can efficiently schedule replacement intervals with minimal effort. Up to eight sensors can be connected to a single LifeMonitor unit, making it ideal for emanding applications such as ship-to-shore (STS) cranes, ship unloaders or steel mills. Rope drum couplings can be monitored in one or two load directions. Furthermore, the wear condition of multiple systems can be centrally recorded and analysed, allowing early detection of misalignment in the drivetrain, which impacts the lifespan of barrel couplings and helps prevent unexpected downtime.

Successful implementation in ship-to-shore hoisting systems

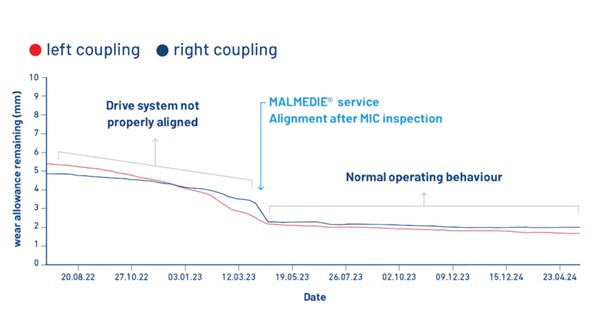

A real-world example highlights the efficiency of LifeMonitor technology: at the Container Terminal Tollerort, operated by Hamburger Hafen und Logistik, the wear condition of two barrel couplings was monitored and analysed.

Before realigning the drivetrain, coupling one exhibited a wear rate of approximately 8mm per year, equating to a one-year service life. After realignment in April, this value significantly improved to 0.42mm per year, which was immediately detected by the LifeMonitor system and translated into an expected remaining service life of five years. For coupling two, the post-alignment wear rate was determined to be 0.5mm per year, translating to an operational lifespan of approximately 20 years in a new Malmedie barrel coupling or four years of remaining service life. Continuous wear monitoring with an accuracy of up to 0.1mm sets new standards in monitoring rope drum couplings. It not only provides precise and reliable measurements but also enables early detection of unexpected wear conditions and the proactive planning of necessary maintenance measures. This minimises downtime, reduces operating costs and extends the service life of critical components – marking a significant step towards future-proof digitalisation in crane operations.

Source: OCH_spring issue, Page 52